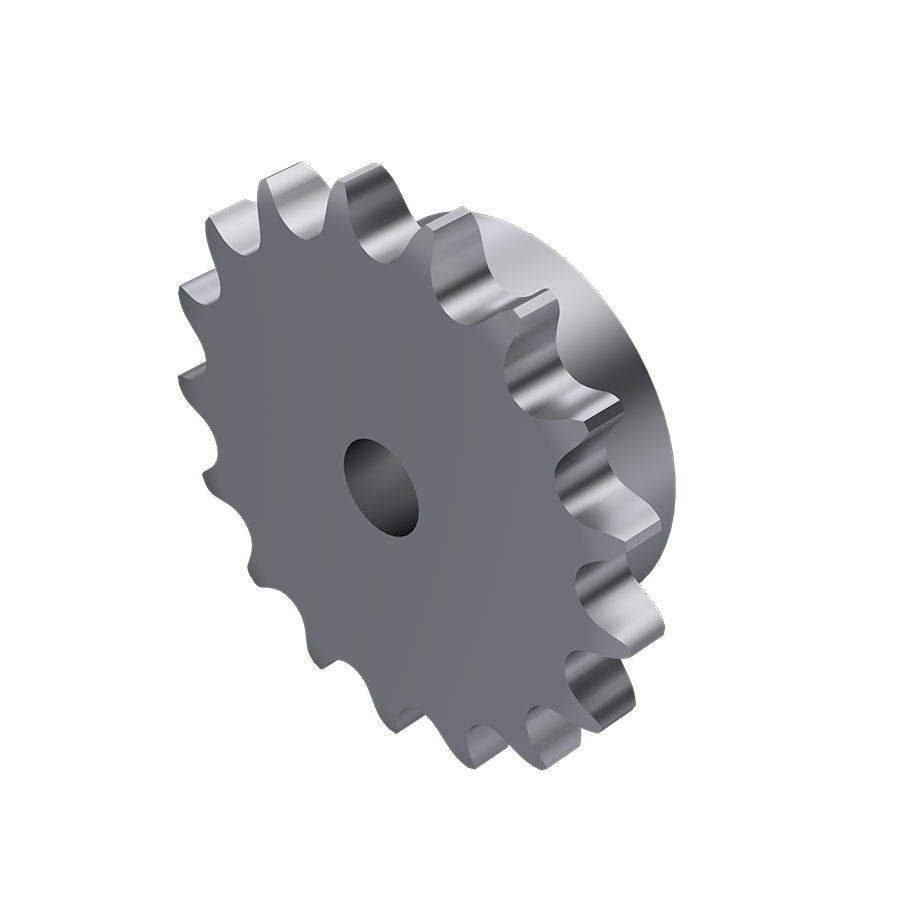

Sintered Gear

These gears are produced by the powder metallurgy method and are formed using sintered metal, a high-strength material. Sinter gears have many advantages and have a wide range of applications.

The primary advantage is the excellent strength properties of sintered gears. Sintered metal materials have a high density and homogeneous structure, which increases the durability and strength of gears. Therefore, sintered gears are effective in applications where high torques and loads must be transferred. They are frequently used in many areas such as agricultural machinery and industrial machinery.

Another advantage is that sintered gears allow the production of complex shapes. This provides flexibility and offers customized solutions in applications requiring special design.

It also provides quiet and vibration-free operation. Thanks to their homogeneous structure and high-strength materials, the contact area of the gears is smooth and stable. This reduces noise and provides quieter operation. Additionally, it reduces vibration and provides a smoother power transmission.

However, it has some limitations. Sintered metal materials have a lower density, which may cause some loss of performance. Additionally, the production process of sintered gears requires special equipment and processes.

| Min | Max | |