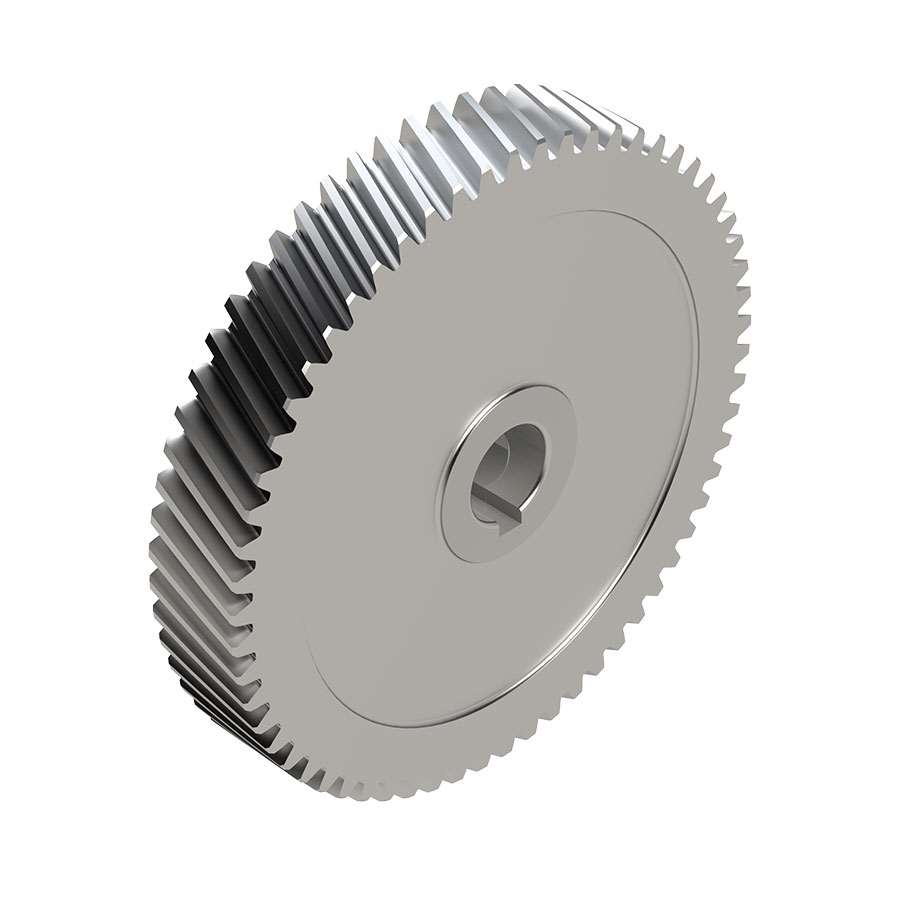

Helical Gear

The tooth profiles of gear wheels are helical, that is, the teeth are wound around the axis along a helical curve. This design offers many advantages over spur gears.

Its primary advantage is quieter operation. These types of gears have a larger tooth surface contact area, which ensures a more homogeneous distribution of power and enables the gears to have a higher load-carrying capacity.

Another important advantage is the ability to operate at higher speeds. Helical gears prevent instantaneous tooth collision, which is the point where the teeth meet at lower speeds. This provides safer and trouble-free operation at high speeds.

Also, the grip feature is better. The helix angle creates a force component at the junction of the gears, which prevents the gears from slipping back and provides a more reliable power transmission. This feature makes helical gears preferred in applications requiring high torque.

Helical gears require a more complex design and manufacturing process. However, when manufactured correctly, helical gears offer high performance and long life.

With correct design and production, they provide reliable and efficient power transmission in mechanical systems.

| Min | Max | |

| Module | 0,8 | 12 |

| Diameter | 8 | 580 mm |